Magnus Force (Spring-Return)

Magnus Force (Spring-Return)

Size:52S to 400S & Torque Output 38 to 37164 (in-lbs)

Operating Temperature:Standard seals: -4 °F to 176 ° F

Viton Seals: 5 °F to 248 °F

Silicone Seals: -31 °F to 176 °F

Air Supply Pressure:Minimum air pressure is 30 PSI

Maximum air pressure is 115 PSI

Supply Air:Dry, lubricated or non-corrosive

Dust below 30 microns

Rotation:90°

Design Standard

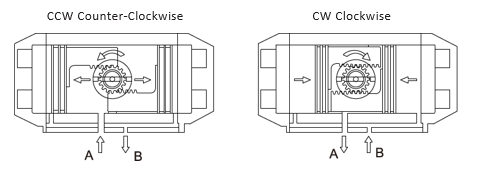

- Air from Port A forces the pistons outward, causing the springs to compress and the pinion to turn counter-clockwise while the spring chamber air exhausts through Port B.

- Upon the loss of air pressure, the springs de-com- press forcing the pistons inwards, causing the pinion to turn clockwise while the air exhausts through Port A.

Specifications

Size Range:

52S to 400S & Torque Output 38 to 37164 (in-lbs)

Temperature:

Standard seals: -4 °F to 176 ° F

Viton Seals: 5 °F to 248 °F

Silicone Seals: -31 °F to 176 °F

Design Features

1.Indicator

Multi-function position indicator with NAMUR mounting, convenient for mounting accessories such as positioners and limit switches.

2.Pinion

The pinion is made from nickel plated steel and conforms to ISO5211, DIN3337, and NAMUR standards. Also available in stainless steel.

3.Actuator Body

According to different requirements, the extruded aluminum alloy ASTM 6005 body can be coated with hard anodized, polyester, PTFE, or nickel.

4.End Caps

The end caps are made of die-cast aluminum and can be coated with polyester, metal powder, PTFE or nickel.

5.Piston

The twin pistons are made of hard anodized coated die-cast aluminum or zinc coated steel. Reverse rotation is achieved by reversing air input for fast operation and long-life span.

6.Stroke Adjustment

Two independent external travel bolts can accurately adjust +5° at both open and closed position.

7.High Performance Spring

Preloaded springs are made from high quality material for resistance to corrosion and long lifespan. Torque requirements can be adjusted by safely and conveniently changing the quantity of springs.

8. Bearings and Guides

Made from low friction, long-life compound material to avoid the direct contact between metals. Maintenance and replacement are easy and convenient.

9.O-Rings

NBR O-Rings trouble free operation at standard temperature ranges. Viton or silicone options are available for high and low temperature applications.

Applications

- Automotive

- Chemical

- Downstream Hydrocarbons

- Food & Beverage

- Energy & Onsite Utilities

- Life Sciences & Medical

- Mining, Minerals & Metals

- Water & Wastewater

- OEM / Engineered Solutions Providers

- Marine

- Oil & GAS

- Power Generation

- Pulp &Paper

Chart or Graph

Output Torque for PDC Series Double Acting Actuators (in-lbs)

PDC Series MAGNUS FORCE (in-lbs)

| Air Supply Pressure | 40 PSI | 50 PSI | 60 PSI | 65 PSI | 80 PSI | 90 PSI | 115 PSI | Spring Output Torque | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Spring Qty. | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° |

| 52S | 5 | 50 | 34 | 67 | 50 | 55 | 38 | ||||||||||

| 52S | 6 | 43 | 22 | 61 | 40 | 96 | 75 | 65 | 44 | ||||||||

| 52S | 7 | 35 | 12 | 53 | 29 | 87 | 65 | 124 | 76 | 52 | |||||||

| 52S | 8 | 46 | 18 | 81 | 53 | 117 | 125 | 152 | 125 | 88 | 59 | ||||||

| 52S | 9 | 38 | 7 | 73 | 42 | 109 | 113 | 144 | 113 | 180 | 149 | 98 | 67 | ||||

| 52S | 10 | 65 | 32 | 102 | 103 | 137 | 103 | 173 | 138 | 110 | 75 | ||||||

| 52S | 11 | 58 | 20 | 94 | 92 | 129 | 92 | 165 | 127 | 200 | 162 | 120 | 82 | ||||

| 52S | 12 | 86 | 81 | 122 | 81 | 158 | 108 | 193 | 151 | 131 | 90 | ||||||

| 63S | 5 | 101 | 68 | 133 | 101 | 197 | 132 | 92 | 60 | ||||||||

| 63S | 6 | 89 | 50 | 120 | 82 | 185 | 147 | 250 | 111 | 73 | |||||||

| 63S | 7 | 76 | 32 | 111 | 64 | 173 | 128 | 237 | 129 | 85 | |||||||

| 63S | 8 | 96 | 45 | 161 | 110 | 226 | 239 | 290 | 239 | 355 | 304 | 148 | 96 | ||||

| 63S | 9 | 149 | 92 | 213 | 220 | 278 | 220 | 343 | 285 | 166 | 109 | ||||||

| 63S | 10 | 124 | 73 | 202 | 202 | 266 | 202 | 330 | 266 | 396 | 331 | 185 | 121 | ||||

| 63S | 11 | 190 | 183 | 254 | 183 | 319 | 248 | 383 | 312 | 203 | 133 | ||||||

| 63S | 12 | 177 | 165 | 242 | 165 | 306 | 229 | 371 | 295 | 221 | 145 | ||||||

| 75S | 5 | 128 | 94 | 172 | 137 | 261 | 227 | 128 | 93 | ||||||||

| 75S | 6 | 110 | 67 | 153 | 112 | 243 | 201 | 332 | 154 | 112 | |||||||

| 75S | 7 | 92 | 42 | 135 | 86 | 224 | 176 | 313 | 180 | 131 | |||||||

| 75S | 8 | 116 | 60 | 204 | 150 | 295 | 327 | 382 | 327 | 472 | 416 | 205 | 150 | ||||

| 75S | 9 | 186 | 125 | 276 | 302 | 364 | 302 | 453 | 391 | 231 | 168 | ||||||

| 75S | 10 | 168 | 98 | 255 | 276 | 345 | 276 | 435 | 365 | 523 | 453 | 257 | 187 | ||||

| 75S | 11 | 239 | 250 | 239 | 250 | 416 | 340 | 504 | 428 | 282 | 205 | ||||||

| 75S | 12 | 220 | 225 | 220 | 225 | 397 | 313 | 486 | 402 | 307 | 224 | ||||||

| 83S | 5 | 206 | 142 | 275 | 212 | 414 | 351 | 204 | 140 | ||||||||

| 83S | 6 | 178 | 102 | 248 | 171 | 387 | 311 | 526 | 244 | 168 | |||||||

| 83S | 7 | 150 | 61 | 219 | 131 | 358 | 270 | 497 | 285 | 196 | |||||||

| 83S | 8 | 192 | 89 | 331 | 228 | 470 | 506 | 609 | 506 | 748 | 645 | 326 | 224 | ||||

| 83S | 9 | 303 | 189 | 442 | 466 | 581 | 466 | 719 | 605 | 366 | 252 | ||||||

| 83S | 10 | 274 | 147 | 413 | 425 | 552 | 425 | 691 | 564 | 830 | 702 | 407 | 280 | ||||

| 83S | 11 | 386 | 384 | 525 | 384 | 664 | 523 | 802 | 662 | 448 | 308 | ||||||

| 83S | 12 | 358 | 344 | 497 | 344 | 635 | 482 | 774 | 621 | 489 | 336 | ||||||

| Air Supply Pressure | 40 PSI | 50 PSI | 60 PSI | 65 PSI | 80 PSI | 90 PSI | 115 PSI | Spring Output Torque | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Spring Qty. | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° |

| 92S | 5 | 277 | 195 | 391 | 212 | 591 | 495 | 304 | 206 | ||||||||

| 92S | 6 | 251 | 135 | 350 | 171 | 551 | 434 | 751 | 365 | 248 | |||||||

| 92S | 7 | 211 | 73 | 309 | 131 | 509 | 373 | 710 | 426 | 289 | |||||||

| 92S | 8 | 277 | 112 | 468 | 312 | 668 | 712 | 868 | 712 | 1068 | 912 | 487 | 330 | ||||

| 92S | 9 | 427 | 251 | 628 | 651 | 828 | 651 | 1027 | 851 | 548 | 372 | ||||||

| 92S | 10 | 386 | 190 | 586 | 590 | 786 | 590 | 985 | 789 | 1186 | 990 | 608 | 413 | ||||

| 92S | 11 | 544 | 530 | 744 | 530 | 943 | 729 | 1144 | 929 | 669 | 455 | ||||||

| 92S | 12 | 503 | 469 | 703 | 469 | 902 | 668 | 1102 | 868 | 730 | 496 | ||||||

| 105S | 5 | 451 | 296 | 597 | 442 | 890 | 735 | 435 | 280 | ||||||||

| 105S | 6 | 396 | 208 | 541 | 354 | 834 | 648 | 1127 | 523 | 336 | |||||||

| 105S | 7 | 340 | 121 | 486 | 268 | 778 | 561 | 1071 | 610 | 392 | |||||||

| 105S | 8 | 429 | 181 | 722 | 474 | 1015 | 1059 | 1307 | 1059 | 1600 | 1352 | 697 | 448 | ||||

| 105S | 9 | 666 | 387 | 959 | 972 | 1252 | 972 | 1544 | 1265 | 784 | 504 | ||||||

| 105S | 10 | 610 | 296 | 903 | 882 | 1196 | 882 | 1489 | 1174 | 1781 | 1467 | 871 | 560 | ||||

| 105S | 11 | 847 | 797 | 1139 | 797 | 1432 | 1090 | 1724 | 1382 | 959 | 616 | ||||||

| 105S | 12 | 791 | 713 | 1084 | 713 | 1376 | 1005 | 1669 | 1298 | 1045 | 672 | ||||||

| 125S | 5 | 646 | 416 | 867 | 637 | 1310 | 1080 | 699 | 460 | ||||||||

| 125S | 6 | 558 | 274 | 779 | 496 | 1221 | 947 | 1664 | 832 | 558 | |||||||

| 125S | 7 | 460 | 133 | 682 | 354 | 1124 | 797 | 1575 | 974 | 646 | |||||||

| 125S | 8 | 593 | 221 | 1036 | 664 | 1478 | 1558 | 1921 | 1558 | 2372 | 2000 | 1106 | 743 | ||||

| 125S | 9 | 947 | 522 | 1390 | 1407 | 1832 | 1407 | 2275 | 1859 | 1248 | 832 | ||||||

| 125S | 10 | 850 | 389 | 1292 | 1275 | 1735 | 1275 | 2186 | 1717 | 2629 | 2168 | 1390 | 929 | ||||

| 125S | 11 | 1204 | 1133 | 1646 | 1133 | 2089 | 1575 | 2531 | 2018 | 1531 | 1018 | ||||||

| 125S | 12 | 1106 | 1000 | 1558 | 1000 | 2000 | 1443 | 2443 | 1885 | 1664 | 1106 | ||||||

| 140S | 5 | 1133 | 752 | 1513 | 1124 | 2266 | 1885 | 1142 | 761 | ||||||||

| 140S | 6 | 982 | 522 | 1363 | 903 | 2115 | 1655 | 2876 | 1372 | 912 | |||||||

| 140S | 7 | 832 | 292 | 1213 | 673 | 1965 | 1434 | 2726 | 1602 | 1062 | |||||||

| 140S | 8 | 1062 | 443 | 1814 | 1204 | 2576 | 2717 | 3328 | 2717 | 4089 | 3469 | 1823 | 1213 | ||||

| 140S | 9 | 1655 | 974 | 2416 | 2487 | 3169 | 2487 | 3930 | 3248 | 2053 | 1372 | ||||||

| 140S | 10 | 1505 | 743 | 2266 | 2257 | 3018 | 2257 | 3779 | 3009 | 4532 | 3770 | 2283 | 1522 | ||||

| 140S | 11 | 2106 | 2027 | 2868 | 2027 | 3620 | 2779 | 4381 | 3540 | 2514 | 1673 | ||||||

| 140S | 12 | 1956 | 1797 | 2717 | 1797 | 3469 | 2558 | 4231 | 3310 | 2744 | 1823 | ||||||

| 160S | 5 | 1708 | 1097 | 2292 | 1690 | 3469 | 2868 | 0 | 1841 | 1239 | |||||||

| 160S | 6 | 1460 | 735 | 2053 | 1319 | 3231 | 2496 | 4408 | 2213 | 1487 | |||||||

| 160S | 7 | 1213 | 363 | 1797 | 947 | 2974 | 2124 | 4151 | 2584 | 1735 | |||||||

| 160S | 8 | 1558 | 584 | 2735 | 1761 | 3912 | 4116 | 5089 | 4116 | 6266 | 5293 | 2947 | 1974 | ||||

| 160S | 9 | 2478 | 1390 | 3655 | 3744 | 4833 | 3744 | 6010 | 4921 | 3319 | 2222 | ||||||

| 160S | 10 | 2239 | 1018 | 3416 | 3372 | 4594 | 3372 | 5771 | 4549 | 6948 | 5726 | 3691 | 2469 | ||||

| 160S | 11 | 3169 | 3009 | 4346 | 3009 | 5523 | 4186 | 6700 | 5364 | 4054 | 2717 | ||||||

| 160S | 12 | 2921 | 2638 | 4098 | 2638 | 5275 | 3815 | 6452 | 4992 | 4425 | 2965 | ||||||

| Air Supply Pressure | 40 PSI | 50 PSI | 60 PSI | 65 PSI | 80 PSI | 90 PSI | 115 PSI | Spring Output Torque | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Spring Qty. | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° |

| 190S | 5 | 2938 | 1965 | 3877 | 2912 | 5762 | 4797 | 2735 | 1770 | ||||||||

| 190S | 6 | 2584 | 1425 | 3523 | 2363 | 5408 | 4248 | 7293 | 3284 | 2124 | |||||||

| 190S | 7 | 2230 | 876 | 3169 | 1814 | 5054 | 3700 | 6939 | 3832 | 2478 | |||||||

| 190S | 8 | 2815 | 1266 | 4700 | 3151 | 6585 | 6921 | 8470 | 6921 | 10347 | 8806 | 4381 | 2832 | ||||

| 190S | 9 | 4346 | 2611 | 6231 | 6373 | 8116 | 6373 | 10001 | 8258 | 4930 | 3186 | ||||||

| 190S | 10 | 3992 | 2062 | 5877 | 5824 | 7762 | 5824 | 9647 | 7709 | 11524 | 9594 | 5470 | 3540 | ||||

| 190S | 11 | 5523 | 5284 | 7408 | 5284 | 9293 | 7160 | 11178 | 9045 | 6019 | 3894 | ||||||

| 190S | 12 | 5169 | 4735 | 7054 | 4735 | 8939 | 6620 | 10824 | 8497 | 6567 | 4248 | ||||||

| 210S | 5 | 3452 | 2522 | 4629 | 3700 | 6983 | 6054 | 3363 | 2434 | ||||||||

| 210S | 6 | 2965 | 1850 | 4142 | 3027 | 6496 | 5381 | 8851 | 4036 | 2921 | |||||||

| 210S | 7 | 2478 | 1177 | 3655 | 2354 | 6010 | 5594 | 8364 | 4709 | 3408 | |||||||

| 210S | 8 | 3169 | 1682 | 5523 | 4036 | 7877 | 8745 | 10231 | 8745 | 12586 | 11099 | 5381 | 3894 | ||||

| 210S | 9 | 5036 | 3363 | 7390 | 8072 | 9745 | 8072 | 12099 | 10426 | 6054 | 4381 | ||||||

| 210S | 10 | 4549 | 2691 | 6904 | 7399 | 9417 | 7399 | 11612 | 9754 | 13966 | 12108 | 6727 | 4868 | ||||

| 210S | 11 | 6417 | 6727 | 8771 | 6727 | 11125 | 9081 | 13480 | 11435 | 7399 | 5355 | ||||||

| 210S | 12 | 5930 | 6054 | 8284 | 6054 | 10639 | 8408 | 12993 | 10763 | 8072 | 5841 | ||||||

| 240S | 5 | 4886 | 3620 | 6585 | 5310 | 9992 | 8718 | 4903 | 3629 | ||||||||

| 240S | 6 | 4160 | 2629 | 5505 | 4328 | 9267 | 7736 | 12674 | 5886 | 4355 | |||||||

| 240S | 7 | 3434 | 1655 | 5133 | 3354 | 8532 | 6762 | 11940 | 6859 | 5089 | |||||||

| 240S | 8 | 4408 | 2372 | 7815 | 5780 | 11214 | 12586 | 14621 | 12586 | 18029 | 15993 | 7842 | 5806 | ||||

| 240S | 9 | 7081 | 4797 | 10488 | 11603 | 13887 | 11603 | 17294 | 15011 | 8833 | 6541 | ||||||

| 240S | 10 | 6355 | 3815 | 9762 | 10630 | 13170 | 10630 | 16569 | 14037 | 19976 | 17436 | 9807 | 7266 | ||||

| 240S | 11 | 9037 | 9647 | 12444 | 9647 | 15852 | 13046 | 19259 | 16454 | 10789 | 7992 | ||||||

| 240S | 12 | 8311 | 8665 | 11710 | 8665 | 15117 | 12064 | 18525 | 15471 | 11771 | 8718 | ||||||

| 270S | 5 | 7992 | 5974 | 10577 | 8568 | 15745 | 13736 | 6966 | 4956 | ||||||||

| 270S | 6 | 6992 | 4594 | 9585 | 7178 | 14754 | 12356 | 19932 | 8346 | 5948 | |||||||

| 270S | 7 | 6010 | 3195 | 8603 | 5788 | 13772 | 10957 | 18949 | 9745 | 6930 | |||||||

| 270S | 8 | 7612 | 4399 | 12780 | 9568 | 17958 | 19932 | 23136 | 19932 | 28314 | 25101 | 11134 | 7921 | ||||

| 270S | 9 | 11789 | 8169 | 16967 | 18533 | 22145 | 18533 | 27322 | 23702 | 12533 | 8913 | ||||||

| 270S | 10 | 10798 | 6789 | 15976 | 17144 | 21153 | 17144 | 26322 | 22313 | 31509 | 27499 | 13913 | 9904 | ||||

| 270S | 11 | 14984 | 15745 | 20162 | 15745 | 25331 | 20923 | 30517 | 26101 | 15312 | 10895 | ||||||

| 270S | 12 | 14002 | 14365 | 19180 | 14365 | 24348 | 19534 | 29526 | 24711 | 16701 | 11878 | ||||||

| 300S | 5 | 9709 | 6452 | 9391 | 6461 | ||||||||||||

| 300S | 6 | 8275 | 4372 | 11648 | 7744 | 11267 | 7753 | ||||||||||

| 300S | 7 | 6833 | 2283 | 10205 | 5656 | 16958 | 12409 | 13143 | 9045 | ||||||||

| 300S | 8 | 8771 | 3567 | 15524 | 10267 | 22277 | 15020 | 10338 | |||||||||

| 300S | 9 | 14090 | 8231 | 20844 | 21737 | 27597 | 21737 | 16896 | 11630 | ||||||||

| 300S | 10 | 12657 | 6151 | 19410 | 19658 | 26163 | 19658 | 32916 | 26411 | 39669 | 33164 | 18781 | 12922 | ||||

| 300S | 11 | 17967 | 17569 | 24720 | 17569 | 31473 | 24322 | 38226 | 31075 | 20658 | 14214 | ||||||

| 300S | 12 | 16533 | 15480 | 23286 | 15480 | 30039 | 22233 | 36793 | 28986 | 22534 | 15507 | ||||||

| Air Supply Pressure | 40 PSI | 50 PSI | 60 PSI | 65 PSI | 80 PSI | 90 PSI | 115 PSI | Spring Out- put Torque | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Spring Qty. | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° |

| 350S | 5 | 13745 | 8532 | 15064 | 10382 | ||||||||||||

| 350S | 6 | 11435 | 5187 | 16489 | 10240 | 18082 | 12462 | ||||||||||

| 350S | 7 | 9125 | 1841 | 14179 | 6895 | 24295 | 17011 | 21091 | 14533 | ||||||||

| 350S | 8 | 11869 | 3549 | 21985 | 13666 | 32093 | 24109 | 16613 | |||||||||

| 350S | 9 | 19684 | 10311 | 29526 | 30526 | 39899 | 30526 | 27119 | 18693 | ||||||||

| 350S | 10 | 17374 | 6966 | 27482 | 27181 | 37589 | 27181 | 47706 | 37297 | 57813 | 47405 | 30137 | 20764 | ||||

| 350S | 11 | 25172 | 23835 | 35279 | 23835 | 45395 | 33951 | 55503 | 44059 | 33146 | 22844 | ||||||

| 350S | 12 | 22870 | 20481 | 32978 | 20481 | 43094 | 30597 | 53202 | 40705 | 36253 | 24924 | ||||||

| 400S | 7 | 17949 | 7691 | 25490 | 16259 | ||||||||||||

| 400S | 8 | 15365 | 3638 | 22569 | 10842 | 29137 | 18587 | ||||||||||

| 400S | 9 | 19994 | 6797 | 34403 | 21206 | 32774 | 20905 | ||||||||||

| 400S | 10 | 17409 | 2753 | 31818 | 17162 | 46227 | 36421 | 23224 | |||||||||

| 400S | 11 | 29234 | 13117 | 43643 | 41935 | 58052 | 41935 | 40058 | 25552 | ||||||||

| 400S | 12 | 26658 | 9072 | 41067 | 37890 | 55477 | 37890 | 69877 | 52290 | 84286 | 66699 | 43705 | 27871 | ||||

| 400S | 13 | 38483 | 33836 | 52892 | 33836 | 67292 | 48237 | 81701 | 62646 | 47343 | 31571 | ||||||

| 400S | 14 | 35907 | 29792 | 50317 | 29792 | 64717 | 44192 | 79126 | 58601 | 50989 | 27526 | ||||||

| 400S | 15 | 33323 | 25747 | 47732 | 25747 | 62132 | 40147 | 76524 | 54556 | 54627 | 23481 | ||||||

| 400S | 16 | 21702 | 45148 | 21702 | 59548 | 36102 | 73957 | 50511 | 58273 | 37164 | |||||||