ElastoTITE™ Grooved End - Series: 831

ElastoTITE™ Grooved End - Series: 831

Size:1” to 12” (Larger size available on request)

Operating Temperature:–40° F to 500° F

Maximum Containment:150 PSI

Design Standard

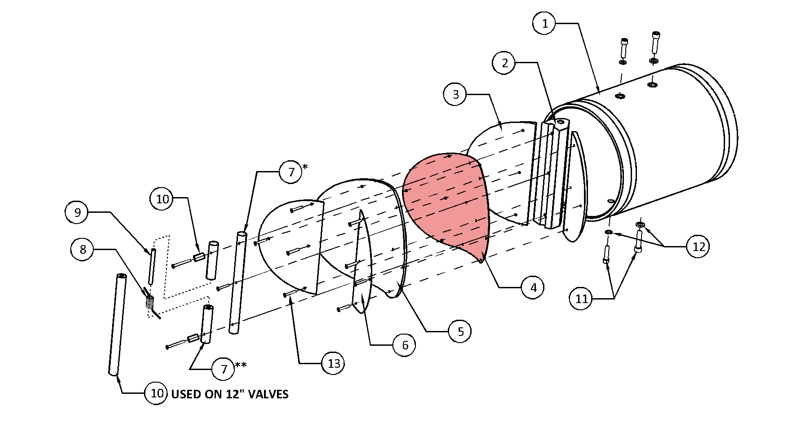

Process Development & Control’s ElastoTITE™ Full Port Elastomer Hinged Check Valves have low pressure loss, lightweight design and a compact construction. Our Patented Flexible Anti-Fatigue Reinforcement Layer design increases the life of the valve and reduces the need for replacement of the elastomer sealing member during routine maintenance. The elastomer hinge check valve design eliminates a restrictive valve seat and increases the valve’s open area and flow coefficient significantly. The ElastoTITE™ Plain End Check Valve is perfect for compressed air and gas systems, water systems and vacuum pumps.

PDC’s Grooved End Elastomer-Hinged Check Valve features a choice of body materials of Carbon Steel or 316 Stainless Steel. The available internals materials are Aluminum and 316 Stainless Steel. Buna-N is the standard seal with available optional seal materials of EPDM, Silicone or Viton.

Materials can be configured to a Maximum Working Pressure of 150 PSI. Operating temperatures range from –40° F to 500° F with available sizes 1” thru 12”. If your application requires unique size and material configurations, please contact the factory for assistance with your special requirements.

Specifications

Size Range:

1” to 12” (Larger size available on request)

Temperature:

–40° F to 500° F

Face to Face:

Short wafer as per ISO 5752 Tab 5 / API 609 Category A

Body Material:

C.I / C.S/ CF8 / CF8M

Sleeve:

FEP/PFA

Disc Material:

C.I / C.S/ CF8 / CF8M

Bush:

PTFE (Teflon)

Design Features

- PDC’s Patented Anti-Fatigue Reinforcement Layer – Our ElastoTITE™ Check Valve’s New Patented Anti-Fatigue Reinforcement Layer is substantially unstretchable and capable of resisting abrasion forces that are encountered while the valve is in operation, increasing the life of the valve significantly.

- Smooth Valve Bore – The smooth machined bore allows the compliant valve seal to maintain a consistent check against backflow.

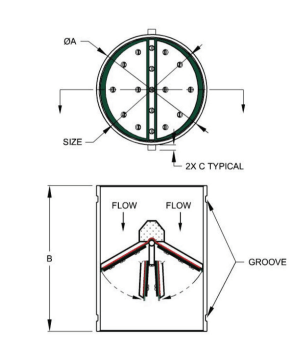

- Grooved End Body – PDC’s Grooved End Series 831 conforms to ANSI/AWWA C-606 specifications for Grooved Ends on both ends of the valve.

- NO Metal-to-Metal Rotating Parts – The motionless Hinge Bar and Seal Clamp design decreases wear of Hinges, Shafts, Valve Plates, and Springs slashing maintenance requirements and costs.

- Full Port Seatless Design – Provides the largest flow area possible with the smallest pressure loss.

- Fast Closure Feature – The closing time is reduced by the valve plate’s minimum travel from an open to a fully closed position.

- Springless Design – Our valves operate without the assistance of a spring in the majority of all applications. With the assistance of a spring, the “slamming” action of the plates is all but eliminated. A spring is recommended when the valve is placed in a vertical downward flow pipeline position.

- Reinforced Valve Seal – Tolerant to liquids, gases, steam, chemical, oil, and fuel. The strength and durability of these elastomers ensure the prolonged life of the valves. The seals provide a tight shutoff.

- Valves can be installed in a pipeline in any position.

- Competitive Pricing – PDC offers competitive pricing, excellent customer service and quick turnaround to meet your needs.

| Valve Size | XXX= | A | B | C |

|---|---|---|---|---|

| 1 | 001 | 1.32 | 5.75 | 0.16 |

| 1-1/4 | 125 | 1.66 | 5.75 | 0.16 |

| 1-1/2 | 150 | 1.9 | 5.75 | 0.16 |

| 2 | 002 | 2.38 | 5.75 | 0.16 |

| 2-1/2 | 250 | 2.88 | 5.75 | 0.25 |

| 3 | 003 | 3.5 | 5.75 | 0.25 |

| 4 | 004 | 4.5 | 6.75 | 0.25 |

| 5 | 005 | 5.56 | 7.75 | 0.35 |

| 6 | 006 | 6.63 | 8.75 | 0.34 |

| 8 | 008 | 8.63 | 10.75 | 0.41 |

| 10 | 010 | 10.75 | 12.75 | 0.56 |

| 12 | 012 | 12.75 | 14.75 | 0.56 |

If your application requires different size and material configurations, please contact the factory for assistance with your special requirements.

Body Materials: Carbon Steel, 316 Stainless Steel

Internal Materials: Aluminum, 316 Stainless Steel, 316 Stainless Steel Spring Option

GENERAL DIMENSIONS (in inches): A = Outside Diameter, B = Face-to-Face, C = Clearance

Sealing Member Materials:

| Material | Temperature |

|---|---|

| Buna-N | 60˚F to 225˚F |

| EPDM | -40˚F to 300˚F |

| Silicone | -100˚F to 500˚F |

| Viton | -20˚F to 400˚F |

Temperature ranges are for general guidance. Range may vary with application.

Standard Models & Materials

| Model | Body | Internals | Seal | Max. Working Pressure (PSI)* |

|---|---|---|---|---|

| 831-XXX-CSAL-BN | Carbon Steel | Aluminum | Buna-N | 150 |

| 831-XXX-CS6S-BN | Carbon Steel | 316 Stainless Steel | Buna-N | 150 |

| 831-XXX-6SAL-BN | 316 Stainless Steel | Aluminum | Buna-N | 150 |

| 831-XXX-6S6S-BN | 316 Stainless Steel | 316 Stainless Steel | Buna-N | 150 |

Note: Process Development & Control’s ElastoTITE Check Valves are designed to work without the assistance of a spring.

A spring option is available.

XXX = SIZE (to be for all sizes)

*Cold Working Pressure (CWP) from -20˚F to 100˚F for 1” thru 12” valve sizes can be up to 200 PSI.